Boost for Flanders and Europe

Project ONE, what is it?

With Project ONE, INEOS is bringing one of Europe’s most energy-efficient and technologically-advanced chemical complexes for the production of ethylene and propylene (olefins) to the Port of Antwerp. A conscious decision for Flanders and Europe, because we have a special bond with the region: INEOS started here in 1998.

With skilled employees and excellent partnerships, this is where we can fully focus on innovation.

So, Project ONE is just the beginning of better for Flanders and Europe:

- Extra jobs

up to 15 million man-hours during the construction, 450 permanent high-value jobs and many more indirect jobs - A solid boost for the local economy

by entering into local partnerships, for example - Showing the way to sustainable industry today

by building a state-of-the-art olefins complex with the most advanced technologies - Making the European industry and economy stronger

by increasing competitiveness with respect to Asia and the US and attracting other investments

It has been more than 20 years since an ethylene plant (ethane cracker) was built in Europe. The state-of-the-art technologies that we are employing with Project ONE mean the environmental footprint of our production is much smaller.

Materials for greater well-being

What are we making with Project ONE?

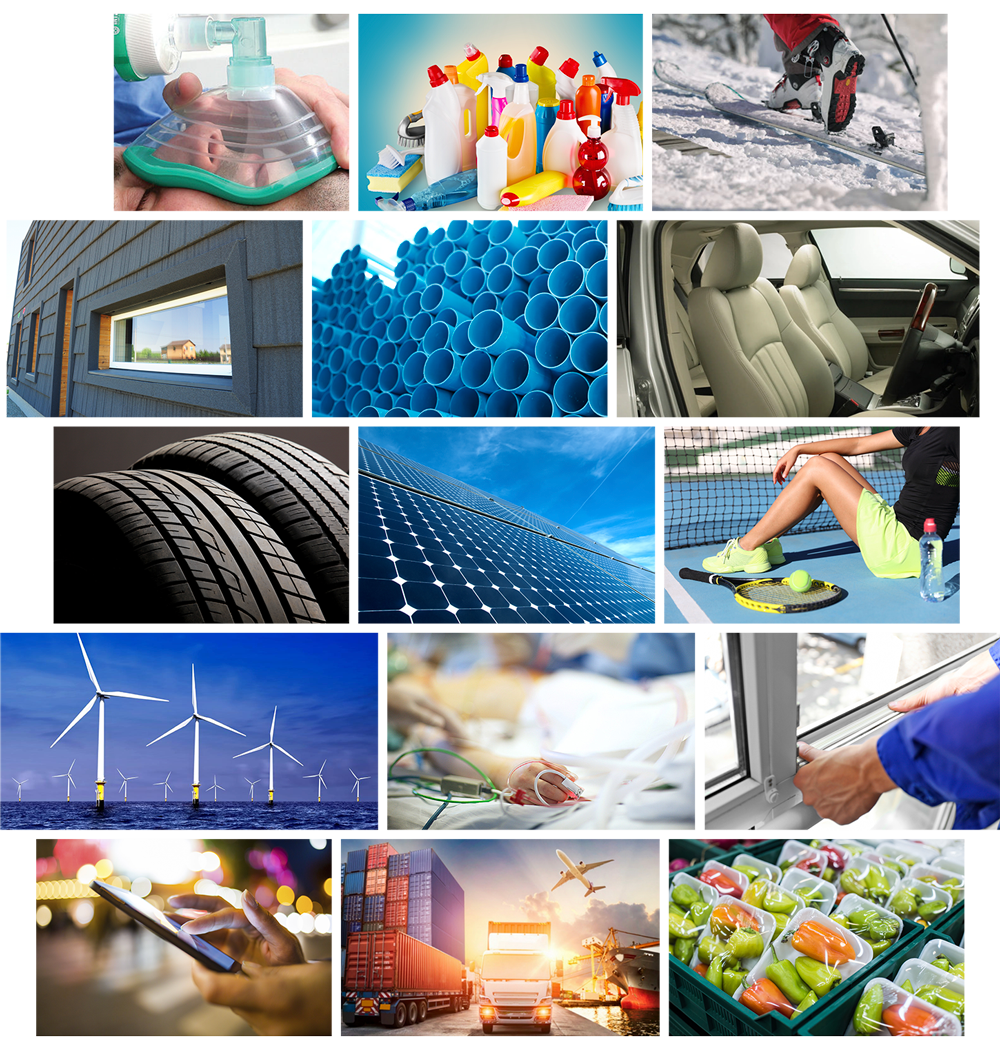

Ethylene and propylene – chemical building blocks for all kinds of sustainable, vital applications: think of light-weight materials in cars, lubricants for wind turbines, disinfectants, or plastic water and gas pipelines that last at least 50 years.

These chemicals also form the basis for packaging, reducing food waste by extending the shelf life of fresh produce from days to over a week or keeping medical devices sterile.

And we’re committed to using our materials responsibly. How? By developing recycling programmes and opting for a circular approach.

The moulds for making contact lenses are made of polypropylene. And the boxes for storing them are made of polyethylene.

Big step towards a more sustainable industry

What is the impact of Project ONE?

Reducing CO2 emissions. Energy-efficient production and transport. Using hydrogen for carbon-free energy. At INEOS, we’re always looking for ways to work more sustainably.

In addition, for Project ONE we are using the very latest technologies to reduce our energy intensity and environmental footprint. And thus help achieve our climate goals (and those of Flanders and Europe).

In reality – With Project ONE, we will produce over 2 million tons of olefins (ethylene and propylene) per year. In the process, our emissions will be less than half of the average of the top 5 olefin plants in Europe. In this way, we are raising the bar in terms of sustainability for our peers in the chemical industry. We are taking a major step towards a more sustainable industry – and we are working with the chemical sector on a climate-neutral future.

Discover here the concrete ways in which we reduce the Project ONE’s footprint.

Together with 7 other leading players in the Port of Antwerp, we are studying the feasibility of a CO2 infrastructure for CCUS (Carbon Capture Utilization & Storage).