-

Where is INEOS building Project ONE?

We are building the ethane cracker in Lillo, on the right bank of the Scheldt, amidst other chemical plants. We are thus doing infill development by building in the industrial zone in the port of Antwerp.

-

What will be built? What will be produced?

With Project ONE, INEOS is building a new ethane cracker. In addition, the site will be equipped with the necessary infrastructure and utilities, including a steam and power generation plant and a quay for loading and unloading ships. There will also be a new office building on the site, warehouses for spare parts and maintenance,…

The ethane cracker which will produce ethylene – an essential building block for numerous high-quality products in the automotive, construction, energy and medical sectors (among others). For example, pipes for transporting drinking water and gas, insulation materials, textiles, solar panels, windmill lubricants and blades, sterile packaging, MRI scanners, recyclable packaging, and lightweight parts for cars.

-

What raw material does Project ONE use?

There is often confusion between raw materials and fuels used in the chemical industry. Fuels are burned for heating or transport, for example. In contrast, raw materials or feedstock are at the basis of a production process and are therefore not burned but used to create value-added products.

Project ONE uses ethane as its feedstock. More than 88% of the carbon in the feedstock ends up in products that retain this carbon and is therefore not emitted.

Ethane is the right feedstock to produce ethylene with the smallest carbon footprint. It replaces ethylene produced in Europe in older, more carbon-emitting plants that use naphtha as a feedstock. Project ONE’s carbon emissions are not even half of the 10% best European steam crackers today, we are doing three times better than the average cracker.

The large volumes of hydrogen released during the ethane cracking process will be repurposed by INEOS as a low-carbon fuel instead of natural gas. As much as 60% of the energy requirements of the crackers and steam boilers can thus be met without recourse to fossil sources.

-

How does an ethane cracker differ from a naphtha cracker?

Today, ethylene is produced in two ways: ethane-based and petroleum-based (naphtha). Today, naphtha is the most widely used raw material in Europe. Project ONE, however, will work on the basis of ethane, a by-product of natural gas.

Ethane is today the most efficient feedstock for ethylene production. This is because the molecular structure of ethane already closely approximates that of ethylene. Naphtha is less selective for ethane: its cracking releases many more by-products. To produce 1.45 million tonnes of ethylene, our cracker consumes 1.9 million tonnes of ethane, while a naphtha cracker needs 4.8 million tonnes of naphtha. That’s more than double.

Moreover, crude oil has to undergo a lot of refining steps before it can be used as naphtha. Ethane production, as in Project ONE, emits less than half the CO2 compared to the naphtha-based alternative for this reason, among others.

To trigger the chemical reaction of cracking, you need a lot of heat and thus energy. Project ONE will get this energy from the hydrogen automatically released during ethane cracking. With this, we can already fill 60% of the heat requirement. In petroleum, there are on average only 2 hydrogen atoms per carbon, in ethane there are 3. So in a naphtha cracker, you will always have to sacrifice part of the petroleum as fuel to make the cracking process possible. With ethane, you choose the most energy-efficient production process, which contributes to much lower CO2 emissions.

INEOS also has its own naphtha crackers, which play an important role for the circular economy with chemical recycling and bio-based feedstock. However, for the production of pure ethylene, naphtha crackers are not as efficient as the Project ONE ethane cracker, so this is the best and most environmentally friendly way to produce pure ethylene. Instead of talking about a “fossil lock-in”, let’s talk about a “naphtha lock-in”. Project ONE’s ethane cracker will reshuffle the market by making CO2 more expensive for the oldest and most polluting installations.

-

Why is this a game-changer for the chemical industry?

All recent major chemical investments have been made in Asia, the Middle East or the United States – which threatened to make Europe dependent on these other parts of the world. Project ONE will make European chemistry more competitive and have a positive effect on employment and prosperity in Antwerp and Flanders.

Using state-of-the-art technologies, Project ONE will become the most energy-efficient production site in Europe (compared to similar European plants), with a substantially smaller footprint. Project ONE will generate almost one and a half million tons of ethylene – an essential building block of the chemical industry. And it will do this with less than half of the CO2 emissions than the 10% best-performing steam crackers in Europe.

If we compare the Project ONE ethane cracker with all other European crackers within the European Emission Trading System (ETS), we see that we are literally pushing the benchmark. In the steam cracker category, Project ONE emits 0.29 tonnes of CO2 per tonne of product, putting it at 43% of the benchmark (0.68 tonnes). The benchmark is determined by the 10% best-performing production sites. Once our ethane cracker goes online, it will affect the benchmark, which will prompt other players to make additional sustainable investments or they will have to pay more for emission allowances.

Jonas Byns, Project ONE’s lead process engineer, explains how that works in this video

-

What is ethylene used for?

Project ONE will convert ethane to ethylene. Ethylene is one of chemistry’s main building blocks from which many products are constructed that are essential in everyday life: building materials, medical applications, clothing, windmill components, light packaging materials, lightweight parts for cars, and many more.

Want to know more? Watch the video on the production of drinking water pipes or read why ethylene is your sports shoe’s biggest supporter.

-

When will Project ONE be completed?

Construction of Project ONE is well underway and the installation is expected to be operational by the end of 2026.

-

Why is Project ONE being built in Antwerp?

INEOS was founded more than 20 years ago in Antwerp. And since then, we have maintained good relationships with the city and the port. We are strongly convinced that the port of Antwerp – with its entrepreneurship, logistics Infrastructure and well-trained people – is the perfect base for our activities.

Moreover, the port of Antwerp’s location is one of its greatest assets. The direct deep-sea access, the existing pipeline network, and an ecosystem where cross-pollination with sector colleagues is encouraged, make the port of Antwerp unique.

For these reasons, INEOS continues to invest in Antwerp. With the arrival of Project ONE, we are strengthening our presence and increasing the effectiveness of Europe’s chemical sector.

Project ONE thus also plays an important role in keeping production in Antwerp and Europe and provides greater strategic autonomy. With Project ONE, we can produce ethylene here sustainably, competitively and efficiently, which in turn allows other companies to remain competitive with the products they make – and with a lower footprint. In chemistry, there is also such a thing as a short supply chain in which companies organise themselves as efficient clusters that exchange residual flows and raw materials. So the question is do we want a primary industry here in Europe or would we rather import these products (and their derivatives) from regions with less strict environmental standards?

-

What is Project ONE’s added value for the region?

Antwerp, and by extension Flanders, will greatly benefit from the realization of Project ONE. The project will further strengthen the future of chemistry in the region and enrich the existing chemical cluster.

In addition, construction of the site will require millions of man-hours. Once Project ONE is operational, it will employ approximately 450 people (300 high-quality full-time jobs and 150 permanent contractor jobs on site) directly. Project ONE’s activities will also create employment indirectly: every job on the site will generate 5 additional jobs at producers, suppliers, maintenance services, engineering firms, and so on.

-

Why is Project ONE important for Europe?

In the last 20 years, Europe’s share of the global chemical sector has been cut In half. Moreover, for several years now, the European chemical sector has been lagging behind in terms of new investments. Therefore, INEOS made the conscious decision to respond to the growing demand for chemical products by building a state-of-the-art site in Europe. Antwerp was chosen because of the historical connection with our birthplace.

Project ONE will use the latest production technologies which enables it to significantly reduce its impact on the environment and lower its carbon footprint as compared to the current ethylene production in Europe. This technological renewal is a major step towards a more sustainable chemical industry.

-

What is the significance of Project ONE for the European chemicals sector?

Project ONE is the largest and most substantial investment in the European chemical sector in the past 20 years. When this project is completed, Antwerp will have the most energy-efficient and environmentally-friendly ethylene installation in all of Europe. Project ONE thus also brings innovation to the Antwerp chemical cluster, the second largest in the world.

In chemistry, there is also such a thing as a short supply chain in which companies organise themselves as efficient clusters exchanging residual streams and raw materials. If value chains leave Europe, it not only has ecological, economic and geostrategic implications, but it also makes it more difficult to make the sector more sustainable with research and technological innovation. The equivalent ethylene production, by the way, will be built somewhere else in the world – with less stringent environmental requirements. Then we will have to import that ethylene (and all its derivatives that will then also be produced elsewhere).

Moreover, the pandemic and the energy crisis have demonstrated Europe’s vulnerability in terms of industrial building blocks. Strategic autonomy is therefore central to the European Commission’s vision. Project ONE is at the beginning of this value chain. It anchors the local processing of essential building blocks, such as ethylene, thus contributing to the resilience and sustainability of Europe’s industrial foundations. With the realisation of Project ONE, Flanders and the port of Antwerp can play a role in making European industry more sustainable.

-

What does Project ONE mean for the climate?

By employing the latest technologies for Project ONE, INEOS is striving to keep the impact on the climate as low as possible.

CO2

By using the latest technologies, Project ONE’s ethane cracker will emit, on average, less than half of the CO2 than the best performing comparable installations in Europe. The hydrogen which is generated as a by-product during the ethylene production process is used as carbon-free fuel: hydrogen does not release any CO2 when burned. As a result we can significantly reduce the use of natural gas. Our record low footprint raises the bar for older, polluting installations (for example, via the European Union Emissions Trading System). Project ONE emits 0.29 tonnes of CO2 per tonne of product or just 43% of the current EU ETS benchmark value of 0.68 tonnes of CO2 per tonne of product. When Project ONE comes online, it will tighten the EU ETS benchmark value by around 14%. Steam crackers in the EU ETS system that do not meet this lower benchmark value will have to buy additional emission rights to cover emissions or take more emission reduction measures.

Buyers of the ethylene produced by Project ONE will save 2 million tonnes of CO2 per annum as they no longer need to rely on the ethylene from older and more polluting plants.

Jonas Byns, Project ONE’s lead process engineer, explains how that works in this video

Also, the products made from ethylene will ultimately save twice as much CO2 as was necessary for their production – because they make end-products (e.g. cars) lighter and with longer lifetimes.

Carbon capturing

We’re also providing space on the Project ONE site for the collection of CO2. The current technology for capturing CO2 from flue gases is still very energy-intensive, and there is currently no network for discharging the collected CO2. We expect important technological breakthroughs in the near future that will make CO2 capture much more efficient. A study is currently being carried out to realize such a CO2 discharge infrastructure in the port of Antwerp. INEOS is working on this with other players from the port of Antwerp via the Antwerp@C consortium.

Energy consumption

Project ONE guarantees very high energy-efficiency. The maximum recovery of heat and cold flows ensures lower energy consumption. For example, the cold energy of the cryogenic ethane supplied, and the heat of the furnaces of the ethane installations, will be reused elsewhere in the process and less external steam will have to be generated.

Carbon-efficiency

In the design of the ethane cracker, very ‘selective’ technologies have been chosen that contribute to a maximum conversion of the raw materials into high-quality chemicals. This results in a particularly high carbon-efficiency of almost 90% – which is much higher than in installations that use crude oil instead of ethane or propane. This means that barely 10% of the carbon present in the raw materials is converted into CO2, the remainder is converted into a high-quality chemical building block.

-

Does Project ONE make raw materials for disposable products?

Project ONE produces ethylene, a gaseous substance that is an essential building block of chemistry. On the basis of these substances, further down the production chain, products will be made that are inextricably linked to our contemporary life. Just think about it:

- Personal care products such as contact lenses, eyewear, toothbrushes, and cosmetics.

- Electronics such as mobile phones, computers, and coffee machines.

- Essential utilities and applications for our homes such as pipes for transporting drinking water or gas, window frames and doors.

- Healthcare applications such as mouth masks, face shields, syringes, medications and blood/plasma bags.

- Things we use in our leisure time, such as sports equipment and clothing, outdoor furniture, and a TV.

- Products that contribute to a sustainable society such as insulation materials, lightweight parts for cars, solar panels, lubricants for wind turbines, and wind turbine blades.

Most of the INEOS Group’s production is for such applications in construction, automotive, household appliances and the like. Part of INEOS Group’s end products, concerns packaging for the food industry. Packaging is sometimes reviled, but it is important to improve the safety and shelf life of products.

For example, the packaging of a cucumber improves its shelf life by about 11 days. Because there is less food waste, the packaging saves 5 times as much CO2 as was needed to produce it. Alternatives to plastic packaging, such as paper, glass and aluminum, use more resources such as energy and water, and may also require the use of plastics to deliver the required performance. This can result in higher CO2 emissions (see TED-talk by UGent professor Kim Ragaert).

-

Can INEOS meet the condition to become climate neutral with the cracker?

Yes indeed. INEOS itself pointed out in its environmental impact report as early as 2021 the possibility of further phasing out its CO2 emissions to net zero.

How do we do that?

- We considered 3 technologies in the plant design that have the potential to make the ethane cracker climate-neutral: hydrogen, carbon capture and a hybrid solution of electrification and more hydrogen.

- Currently, the hydrogen track is furthest along. It is technically perfectly possible to run the furnaces of the cracker and the steam boilers entirely on hydrogen. We fully reuse the hydrogen released in the cracking process as fuel for the furnaces, which means we can already avoid 60% of natural gas. If enough climate friendly hydrogen is available, we can increase that percentage further.

- Moreover, we will report to the government every 2 years on the evolution of the technical feasibility of the solutions and their possible implementation in practice.

-

How does Project ONE fit into the climate ambitions of the port of Antwerp and the government?

INEOS endorses these ambitions. For example, we support the objectives of the Paris Climate Agreement and the European Green Deal.

And this is not just words. With Project ONE, we are building one of the most energy-efficient and environmentally-friendly installations in Europe. We’re also investing in research into technology for the capture and storage of CO2 (among other research topics). Technology that we already provide space for today on the Project ONE site. Incidentally, we have been capturing CO2 at our INEOS Oxide site in Zwijndrecht for 10 years now, and the captured CO2 is used for industrial use via the BECO2 joint venture, and we collaborated on Greensand, a pioneering project for the storage of CO2 in the North Sea bed.

All our sites have developed a roadmap to become climate neutral by 2050 at the latest. The focus is on reduction at the source by using renewable energy and ‘green heat’, reusing hydrogen and CO2, further investments in electrification and, where possible, switching to recycled or bio-based raw materials. This ambition also takes into account Europe’s target of reducing greenhouse gas emissions by 55% by 2030 compared to 1990 figures.

The route to a climate-neutral future runs in stages. Project ONE is already making a fundamental difference by making maximum use of the very best of what today’s technology offers. Customers supplied with ethylene from Project ONE can reduce their CO2 emissions by 2 million tonnes per year because they are no longer dependent on ethylene from more polluting plants. And our ambition reaches even further. We have incorporated flexibility into our plants to allow us to reduce our footprint further and integrate other technologies as soon as they are mature. For example, it is technologically possible to feed the cracking ovens and steam generators of Project ONE entirely with hydrogen, provided that enough climate-friendly hydrogen is available. With the investments currently being made in hydrogen technology, including in Flanders, it looks like this will be possible in future. Our design also has room for a carbon capture installation, so this option can also be utilised.

-

What about Project ONE’s nitrogen emissions?

To maximise nitrogen emission reductions, Project ONE uses multiple abatement techniques that reduce NOx emissions by 71% from day 1.

Our nitrogen emission for the whole of Flanders is a maximum of 0.09 kg per hectare; for the Brabantse Wal it is a maximum of 0.13 kg per hectare per year. To make tangible what the nitrogen deposition of Project ONE in the Brabantse Wal nature reserve represents in concrete terms: it is a maximum of 0.13 kg of nitrogen against a background of 33 kg per hectare on an annual basis from other sources.

We examined the impact of nitrogen not only for the Brabantse Wal, but also for the Kalmthoutse Heide and all other nearby nature reserves in Flanders and the Netherlands. For Flanders, over 50 habitat types and more than 65 plant and animal species were examined individually. Not only in terms of nitrogen deposition, but also in the context of other environmental pressures such as desiccation and fragmentation. In the Netherlands, more than 35 habitats and species are involved.

We worked extremely hard to document everything. The permit application in itself is a feat on which a lot of experts have worked within INEOS and from other parties. For example, the permit application includes almost 1,800 (building) plans, an environmental impact report of more than 1,000 pages, and various other studies to show that every best available technology (energy-efficient, minimal impact on the environment in terms of water, air, noise, soil protection, etc.) is applied.

The appropriate assessment we have prepared to describe our nitrogen contribution to nearby nature reserves alone runs to 800 pages.

We have taken the comments of the Licensing Disputes Board to heart and added more depth to the ecological approach compared to our previous version.

-

Should INEOS not produce more bio-based plastics?

The introduction of bio-based raw materials for the production of plastics is a very promising evolution. Although it is not yet possible to make all plastics from bio-based raw materials, we are fully committed to increasing the amount of bio-based raw materials we use, especially in Belgium:

- Biovyn, production of PVC from biomass: at our INOVYN site in Jemeppe, we have made it possible to produce PVC with ethylene produced from a biomass that does not compete with food production. In this way, there is a reduction of CO2 emissions of more than 90 percent compared to production from fossil raw materials. This supply chain has been fully certified by the Roundtable on Sustainable Biomaterials (RSB), an independent third party. Biovyn can be found, for example, in the upholstery of the Polestar 3 car, but also in prosthetics and window profiles.

- Bio-attribution of renewable raw materials: ‘bio-attribution’ expresses the extent to which fossil raw materials have been replaced by renewable or bio-based raw materials. Ineos O&P North Lillo offers a range of Bio-Attributed Olefins and Polyolefins, based on renewable bio-based raw materials that do not compete with food production. Their supply chain is fully certified by the Roundtable on Sustainable Biomaterials (RSB), an independent third party.

-

Will Project ONE produce plastic that ends up in the environment?

The basic chemicals produced are building block of numerous products from our daily life. Think of insulation materials, pipes, lightweight materials that reduce car fuel consumption and emissions, medical applications such as disinfectant hand gel, syringes, intravenous bags, MRI scanning devices and sterile packaging, wind turbines, packaging materials that lengthen the storage time of foods, and so on.

Plastics are not intended to end up in the natural environment . It’s not the plastics themselves, but the pollution caused by discarded plastics that we, as a society, must tackle. INEOS’ vision is that we should evolve into a world where plastics are not viewed as disposable products, but valuable materials. That’s why INEOS invests heavily in the advanced recycling of plastics – and today, all of INEOS’ polymers are already recyclable.

We have committed to incorporate at least 850 000 tonnes of recycled and bio-attributed material in our polymer products by 2030. We previously committed to use an average of 30% recycled material in products for polystyrene packaging in Europe by 2025; to market a range of polyolefin products for packaging in Europe with at least 50% recycled material, to ensure that 100% of our polymers are recyclable.

More info in INEOS’ sustainability report and our INEOS Pledge

At the Olefins & Polymers Europe Technology Centre in Neder-over-Heembeek, we made a breakthrough in mechanical recycling with our Recycle-IN products developed and tested in Belgium. There, we developed a booster plastic that makes it possible to integrate at least 50% recycled material into products without loss of quality.

INEOS has also developed a new range of biopolymers based on residues from the pulp and paper industry that can produce plastics with 90% reduction in greenhouse gas emissions

Examples include the first sustainable gas pipeline, made with bio-based polyethylene from INEOS O&P in Lillo and the agreement concluded by INEOS with Plastic Energy for the purchase of raw materials.INEOS supports various initiatives to remove plastics that have ended up in the environment. Just think of Operation Clean Sweep in the port of Antwerp, the Ocean Clean-up, and other sustainability initiatives of the port of Antwerp.

-

Will Project ONE have an impact on the surrounding area?

High standards of safety, health and environment are an essential part of INEOS’ operations. INEOS’ environmental performance is closely monitored in all phases of implementation. We will meet or exceed all applicable environmental standards imposed by the Flemish environmental authorities, now and in the future.

By using hydrogen as a fuel and additional energy savings, Project ONE will perform substantially better in terms of CO2 emissions than the cleanest comparable plants in Europe today: in fact, our carbon emissions will be not even half of the 10% best performing European steam crackers.

-

Should INEOS focus more on recycling instead of producing new plastics?

INEOS is strongly committed to reduce plastic waste. It is not the plastics themselves that are the problem, but the fact that they are thrown away in to the environment, sent to landfill, or incinerated. According to INEOS’ vision, we have to handle plastics with care, precisely because they are such valuable materials. That’s why INEOS invests heavily to support the recycling of plastics. In this way, all polymers produced by us (such as polyethylene and polypropylene produced on the basis of Project ONE-output) can be fully recycled.

INEOS is investing to support different forms of recycling. We develop products that lend themselves to mechanical recycling so that recycled material can also be used for high-quality applications, and we incorporate recycled plastics in to our products. We invest in the development of our processes to use bio-based raw materials or waste plastics as raw materials for new plastics. Advanced recycling (also called chemical recycling) is a developing technology. As we commercialize this technology, we will be able to produce more plastic from recycled products, creating a market for waste plastic.

All this is in line with our commitment of the INEOS Pledge, as plastics are a valuable material. We have committed to incorporate at least 850 000 tonnes of recycled and bio-attributed material in our polymer products by 2030. We previously committed to use an average of 30% recycled material in products for polystyrene packaging in Europe by 2025; to market a range of polyolefin products for packaging in Europe with at least 50% recycled material, to ensure that 100% of our polymers are recyclable.

Here are some concrete examples:

– When you see packaging, you don’t see that it consists of several layers. In fact, all those different layers have specific functions: rigidity, transparency, printability, sealability, barrier…. And to exploit each of these qualities, different materials are combined. Moreover, additional layers are needed to make all those layers compatible. However, these many layers also make packaging more difficult to recycle.

That is why the colleagues at our R&D centre in Neder-Over-Heembeek focused on “mono-materials“. Thus, they developed an upright bag packaging in mono-material that consists of more than 95% polyethylene and is fully recyclable. Indeed, polyethylene has emerged as one of the best monomaterials because of its intrinsic qualities and because the recycling chain was already in place.

It also produced a second rigid MDO monomaterial roll with more than 50% plastic waste – an absolute first in the market. This was helped by the investment in a high-tech, multi-layer MDO line to work with customers to develop solutions that they can apply directly to their own production lines.

Read more about it in this report on our R&D centre in Neder-Over-Heembeek– Upgrading plastics for successful combination with recycled material Each time a polymer (such as polyethylene and polypropylene) is mechanically recycled, the quality of the material decreases. This is why these recyclates are usually used in low performance and rather inexpensive end applications such as flower pots and garbage bags. The goal of INEOS is to increase the value of recycled polymers so that they are equivalent to ‘virgin’ plastics. In our research centre in Neder-Over-Heembeek we have succeeded in making products that meet the demanding performance characteristics required by our customers, whilst containing more than 50% of recycled plastic. These products are now fully commercialised under our Recyl-IN brand name.

– Advanced (chemical) recycling of polyethylene and polypropylene. Instead of making plastics based on naphtha (from crude oil), INEOS has started a partnership with the recycling company Plastic Energy to break down used polyethylene and polypropylene to their base molecules so that they can be reused as a new feedstock. After first successful tests in 2020, INEOS and Plastic Energy are now developing a project to build a new installation that can carry out this process on a large scale.

– Depolymerization of styrene. INEOS Styrolution has already made a breakthrough for chemical recycling by depolymerizing polystyrene waste: laboratory scale production of new polystyrene based on recycled styrene monomers. For example, old yoghurt jars can be reused half in new products. This happens at the site of Styrolution in Antwerp, the largest polystyrene installation in Europe. Soon a partnership will be entered into with waste processing company INDAVER whereby polystyrene waste will be recycled into pure styrene monomers. Already in 2022, a demo plant will be operational that will be able to recycle 15,000 tons. This project fits in Styrolution’s efforts to make plastic products based on waste or renewable raw materials.

-

Will Project ONE cause additional pellets to enter the port and nature?

Project ONE does not produce pellets. The ethylene and by-products produced are gases that, under high pressure in the liquid state, will be transported mainly through pipelines to other industrial sites in the port, Belgium, the Netherlands and Germany. A portion will be cooled and liquefied to be transported by ship to the final destination.

-

How will INEOS limit inconvenience to the neighborhood?

Logistics and transport

During Project ONE’s construction, maximum use will be made of ship transport to minimize the burden on road traffic in the neighborhood. A modular design was chosen, whereby large modules are produced off-site and then transferred by ship to the site in Lillo. In this way, we can significantly reduce both the construction time and any local inconvenience.

Ethane, the raw material of the Project ONE installation, is supplied by ship. When the installations are put into operation, the ethylene produced will be transported via pipelines: the safest and most ecological method of transport, which relieves road traffic as much as possible.

Moreover, the ethane that INEOS imports into Antwerp will be transported by a new generation of ships that are themselves powered by ethane gas rather than heavy fuel oil. Using gas as fuel eliminates sulphur emissions and reduces carbon dioxide emissions compared to conventional fuels.

Noise – light – odour

We’re striving for the lowest possible noise emissions during the construction of the installation. The use of ground flares will limit visible flare activity. The elevation flares serve primarily as a safety system and will only be used to start up and shut down the installation or in the event of a major malfunction. The high reliability requirements of the production units should minimize the need for flaring. The nuisance of odour is not expected: the planned water purification installation will break down the sulfur compounds from the ethane cracker in a closed installation.

Protecting nature and biodiversity

The vegetation on the industrial estate that was removed to prepare the land for construction will be more than compensated for. In order to protect and relocate biodiversity, a large number of measures have been provided for during the construction phase – the relocation of the hairy wood ant and orchids, the preservation of a natural corridor on the site, etc. We are working on these things with the port and independent organizations that are responsible for the conservation of nature.

-

Why is this a game-changer for the chemical industry?

All recent major chemical investments have been made in Asia, the Middle East or the United States – which threatened to make Europe dependent on these other parts of the world. Project ONE will make European chemistry more competitive and have a positive effect on employment and prosperity in Antwerp and Flanders.

Using state-of-the-art technologies, Project ONE will become the most energy-efficient production site in Europe (compared to similar European plants), with a substantially smaller footprint. Project ONE will generate almost one and a half million tons of ethylene – an essential building block of the chemical industry. And it will do this with less than half of the CO2 emissions than the 10% best-performing steam crackers in Europe.

If we compare the Project ONE ethane cracker with all other European crackers within the European Emission Trading System (ETS), we see that we are literally pushing the benchmark. In the steam cracker category, Project ONE emits 0.29 tonnes of CO2 per tonne of product, putting it at 43% of the benchmark (0.68 tonnes). The benchmark is determined by the 10% best-performing production sites. Once our ethane cracker goes online, it will affect the benchmark, which will prompt other players to make additional sustainable investments or they will have to pay more for emission allowances.

Jonas Byns, Project ONE’s lead process engineer, explains how that works in this video

-

Are there no alternative raw materials for the shale gas from the United States?

Today, there is no fully-fledged organic alternative to ethane.

The bio-based alternative bioethanol is only viable and acceptable from a sustainability perspective in places where it does not compete with the food industry. Given the amount of space required to have sufficient volumes, bioethanol is only used in very specific areas (such as Brazil with its sugar beet plantations).

Sugar beet produces 5,000 litres of ethanol per hectare or 3.95 metric tonnes of ethanol/hectare. Applying this to Project ONE: 633,000 hectares of sugar beet are needed to feed an ethane cracker to produce one and a half million ethylene. By comparison, Flanders has 622,000 hectares of agricultural land. So this integral area would not suffice on its own and would mean that this land could not be used for food production.

Similar reasoning applies to the availability of recycled raw material. In 2021, 30 million tonnes of mixed plastic waste was available in Europe. For a cracker with the capacity of Project ONE, you already need a third of that, while you would need 150 million tonnes for Europe’s current ethylene capacity. That is not simply not available right now.

-

How big is Project ONE’s yard/terrain?

The Project ONE project area is as much as 55 hectares or 550,000 m2.

Some other notable figures:

- INEOS invests over 4 billion in Project ONE in Antwerp

- The yard will employ 3,000 people at peak

- 4 km of sheet piling has been installed and 20,000 pile foundations

- 300,000 m3 of soil has been excavated

- The water treatment plant purifies 75 m3 of water per hour

- The actual ethane cracker has a footprint of some 75,000m²

- The diameter of the ethane tank at the site is almost as long as a football field

- 45,000 tonnes of steel will be consumed, equivalent to 6x the Eiffel Tower

- The project will require 1,000’s kilometres of power lines

- Man hours at the Lillo yard are estimated at 8 million; at the foreign yards where the modules are built, it is estimated at 19 million

-

What will be built? What will be produced?

With Project ONE, INEOS is building a new ethane cracker. In addition, the site will be equipped with the necessary infrastructure and utilities, including a steam and power generation plant and a quay for loading and unloading ships. There will also be a new office building on the site, warehouses for spare parts and maintenance,…

The ethane cracker which will produce ethylene – an essential building block for numerous high-quality products in the automotive, construction, energy and medical sectors (among others). For example, pipes for transporting drinking water and gas, insulation materials, textiles, solar panels, windmill lubricants and blades, sterile packaging, MRI scanners, recyclable packaging, and lightweight parts for cars.

-

How will INEOS limit inconvenience to the neighborhood?

Logistics and transport

During Project ONE’s construction, maximum use will be made of ship transport to minimize the burden on road traffic in the neighborhood. A modular design was chosen, whereby large modules are produced off-site and then transferred by ship to the site in Lillo. In this way, we can significantly reduce both the construction time and any local inconvenience.

Ethane, the raw material of the Project ONE installation, is supplied by ship. When the installations are put into operation, the ethylene produced will be transported via pipelines: the safest and most ecological method of transport, which relieves road traffic as much as possible.

Moreover, the ethane that INEOS imports into Antwerp will be transported by a new generation of ships that are themselves powered by ethane gas rather than heavy fuel oil. Using gas as fuel eliminates sulphur emissions and reduces carbon dioxide emissions compared to conventional fuels.

Noise – light – odour

We’re striving for the lowest possible noise emissions during the construction of the installation. The use of ground flares will limit visible flare activity. The elevation flares serve primarily as a safety system and will only be used to start up and shut down the installation or in the event of a major malfunction. The high reliability requirements of the production units should minimize the need for flaring. The nuisance of odour is not expected: the planned water purification installation will break down the sulfur compounds from the ethane cracker in a closed installation.

Protecting nature and biodiversity

The vegetation on the industrial estate that was removed to prepare the land for construction will be more than compensated for. In order to protect and relocate biodiversity, a large number of measures have been provided for during the construction phase – the relocation of the hairy wood ant and orchids, the preservation of a natural corridor on the site, etc. We are working on these things with the port and independent organizations that are responsible for the conservation of nature.

-

What phase is the project in now?

Construction of Project ONE is in full swing. At the site, more than 1,000 people are currently already working on the construction of the ethane cracker and associated infrastructure. In addition, there are many colleagues helping to shape the project.

Moreover, the construction work for Project ONE is not only being done in Antwerp. At various yards elsewhere in the world, large ‘modules’ such as furnaces and ‘piperacks’ are currently being built that will subsequently be shipped to Antwerp. It proved impossible to build those modules in Europe because you need a very large yard with connection to maritime transport as well as specialised labour. Moreover, we save time this way, because you would not be able to work on the foundations and the superstructure on the Project ONE yard at the same time.

Curious to see what it’s like on-site in Antwerp? Then take a look at this video:

Be sure to keep an eye on our social media to stay up to date!

Linkedin – Facebook – Instagram – X/Twitter – YouTube -

When will Project ONE be completed?

Construction of Project ONE is well underway and the installation is expected to be operational by the end of 2026.

-

Does Project ONE receive government support?

First, an important distinction should be made between government support in the form of guarantees and grants.

The Flemish government facilitates investment projects in Flanders through Participatie Maatschappij Vlaanderen (PMV) and Gigarant, a vehicle that provides market-based guarantees for lending to companies. This allows the region to support crucial investments in the economy. The advantage for companies is that lenders are willing to grant larger credit amounts due to this guarantee. There are often conditions attached to this for the company, for example in terms of employment. A win-win, therefore, for both parties. The recent presentation of PMV’s annual results showed that 7,513 guarantees are in place to enable investments in Flemish SMEs and industrial companies. Guarantees of this kind are also common outside Belgium as a support instrument for investors.

In other words, the Gigarant guarantee is not a subsidy or a payment to a company, but a way of facilitating commercial credit with banks. In the case of Project ONE, the Flemish Government is guaranteeing up to €500 million through Gigarant. This is a significant but comparatively small part of the total external financing for the investment which amounts to €3.5 billion. Thus, the Flemish Government guarantees only 14% of the total financing. INEOS is paying a market-based guarantee premium to the Flemish Government for this of as much as 85 million euros over the total term.

The guarantee contract includes an employment guarantee of 250 full-time workers. For Project ONE, INEOS is expected to more than meet this condition and employ 450 full-time direct workers (300 on a payroll basis and about 150 contractors for permanent maintenance) and indirectly a multiple of that.

INEOS Group, which is financially sound, also guarantees repayment to the lenders. Only if the global INEOS Group were to go bankrupt will the lenders be able to recover from the Flemish Government. This chance is virtually nil. So no Flemish tax money will go to INEOS.

No grants for Project ONE have been paid out from the government to date. However, there are some support possibilities from the Flemish government for specific efforts. For this, INEOS must meet the conditions like any other company, including European and Flemish regulations.

If there will be subsidies in the future, it will be for employee training and education or environmental impact mitigation, and this according to government regulations that are the same for all companies. This would allow INEOS to claim one-off support from the Flemish Agency for Innovation and Enterprise (Vlaio) for Project ONE of up to €8 million in total.

In addition, for its efforts in research and development at all its sites (not just Project ONE), INEOS can receive up to €8 million annually.

-

Will Project ONE have an impact on the surrounding area?

High standards of safety, health and environment are an essential part of INEOS’ operations. INEOS’ environmental performance is closely monitored in all phases of implementation. We will meet or exceed all applicable environmental standards imposed by the Flemish environmental authorities, now and in the future.

By using hydrogen as a fuel and additional energy savings, Project ONE will perform substantially better in terms of CO2 emissions than the cleanest comparable plants in Europe today: in fact, our carbon emissions will be not even half of the 10% best performing European steam crackers.

-

Will Project ONE cause additional pellets to enter the port and nature?

Project ONE does not produce pellets. The ethylene and by-products produced are gases that, under high pressure in the liquid state, will be transported mainly through pipelines to other industrial sites in the port, Belgium, the Netherlands and Germany. A portion will be cooled and liquefied to be transported by ship to the final destination.

-

How will INEOS limit inconvenience to the neighborhood?

Logistics and transport

During Project ONE’s construction, maximum use will be made of ship transport to minimize the burden on road traffic in the neighborhood. A modular design was chosen, whereby large modules are produced off-site and then transferred by ship to the site in Lillo. In this way, we can significantly reduce both the construction time and any local inconvenience.

Ethane, the raw material of the Project ONE installation, is supplied by ship. When the installations are put into operation, the ethylene produced will be transported via pipelines: the safest and most ecological method of transport, which relieves road traffic as much as possible.

Moreover, the ethane that INEOS imports into Antwerp will be transported by a new generation of ships that are themselves powered by ethane gas rather than heavy fuel oil. Using gas as fuel eliminates sulphur emissions and reduces carbon dioxide emissions compared to conventional fuels.

Noise – light – odour

We’re striving for the lowest possible noise emissions during the construction of the installation. The use of ground flares will limit visible flare activity. The elevation flares serve primarily as a safety system and will only be used to start up and shut down the installation or in the event of a major malfunction. The high reliability requirements of the production units should minimize the need for flaring. The nuisance of odour is not expected: the planned water purification installation will break down the sulfur compounds from the ethane cracker in a closed installation.

Protecting nature and biodiversity

The vegetation on the industrial estate that was removed to prepare the land for construction will be more than compensated for. In order to protect and relocate biodiversity, a large number of measures have been provided for during the construction phase – the relocation of the hairy wood ant and orchids, the preservation of a natural corridor on the site, etc. We are working on these things with the port and independent organizations that are responsible for the conservation of nature.

-

Will INEOS flare on Project ONE?

Flaring removes flammable gases safely. This is important to ensure the safety of a chemical site, in the interest of all employees and local residents.

Flaring is done primarily when starting and stopping the installations, or with major interruptions such as a power failure. Usually, this will be done via ground flares, in order to limit the impact on the surrounding area. INEOS will examine how it can best inform local residents when the large flaring tower must be used.

-

What about the impact on the surrounding municipalities?

The project area is located in the port of Antwerp (see Where will Project ONE be built?) and surrounded by other industrial and port-related activities. The nearest residential centers are those of Berendrecht (at 1 km) and Lillo Fort and Zandvliet (at approx. 2 km). The effects on the residential environment are also examined objectively in the environmental impact report, to ensure that they satisfy all legal regulations. Measurements are also being taken regularly during the operation of the installations.

Because the site’s final products will be transferred by pipeline to other sites in Belgium, the Netherlands and Germany, this transport does not require ships or trucks, which would additionally burden the road network and the air and noise quality.

-

How is INEOS taking questions and suggestions from local residents into account?

INEOS wishes to maintain an open dialogue and sustainable relationship with the neighbouring companies and residents of our sites. Project ONE will contribute to the region’s prosperity, employment and technological innovation of the sector.

With a dedicated point of contact, we offer the possibility to signal concerns about our activities. So if you are concerned about or bothered by our activities, you can easily report it. Every report is carefully examined and dealt with appropriately.

We are also a member of the Chemical Advisory Board, through which we periodically enter into dialogue with the residents of the surrounding residential areas of Stabroek, Berendrecht and Lillo.

Via this website, we also want to keep the neighborhood informed of the further progress of the works, as we strive to minimize any inconvenience.

-

Does Project ONE make raw materials for disposable products?

Project ONE produces ethylene, a gaseous substance that is an essential building block of chemistry. On the basis of these substances, further down the production chain, products will be made that are inextricably linked to our contemporary life. Just think about it:

- Personal care products such as contact lenses, eyewear, toothbrushes, and cosmetics.

- Electronics such as mobile phones, computers, and coffee machines.

- Essential utilities and applications for our homes such as pipes for transporting drinking water or gas, window frames and doors.

- Healthcare applications such as mouth masks, face shields, syringes, medications and blood/plasma bags.

- Things we use in our leisure time, such as sports equipment and clothing, outdoor furniture, and a TV.

- Products that contribute to a sustainable society such as insulation materials, lightweight parts for cars, solar panels, lubricants for wind turbines, and wind turbine blades.

Most of the INEOS Group’s production is for such applications in construction, automotive, household appliances and the like. Part of INEOS Group’s end products, concerns packaging for the food industry. Packaging is sometimes reviled, but it is important to improve the safety and shelf life of products.

For example, the packaging of a cucumber improves its shelf life by about 11 days. Because there is less food waste, the packaging saves 5 times as much CO2 as was needed to produce it. Alternatives to plastic packaging, such as paper, glass and aluminum, use more resources such as energy and water, and may also require the use of plastics to deliver the required performance. This can result in higher CO2 emissions (see TED-talk by UGent professor Kim Ragaert).

-

What will be built? What will be produced?

With Project ONE, INEOS is building a new ethane cracker. In addition, the site will be equipped with the necessary infrastructure and utilities, including a steam and power generation plant and a quay for loading and unloading ships. There will also be a new office building on the site, warehouses for spare parts and maintenance,…

The ethane cracker which will produce ethylene – an essential building block for numerous high-quality products in the automotive, construction, energy and medical sectors (among others). For example, pipes for transporting drinking water and gas, insulation materials, textiles, solar panels, windmill lubricants and blades, sterile packaging, MRI scanners, recyclable packaging, and lightweight parts for cars.

-

What raw material does Project ONE use?

There is often confusion between raw materials and fuels used in the chemical industry. Fuels are burned for heating or transport, for example. In contrast, raw materials or feedstock are at the basis of a production process and are therefore not burned but used to create value-added products.

Project ONE uses ethane as its feedstock. More than 88% of the carbon in the feedstock ends up in products that retain this carbon and is therefore not emitted.

Ethane is the right feedstock to produce ethylene with the smallest carbon footprint. It replaces ethylene produced in Europe in older, more carbon-emitting plants that use naphtha as a feedstock. Project ONE’s carbon emissions are not even half of the 10% best European steam crackers today, we are doing three times better than the average cracker.

The large volumes of hydrogen released during the ethane cracking process will be repurposed by INEOS as a low-carbon fuel instead of natural gas. As much as 60% of the energy requirements of the crackers and steam boilers can thus be met without recourse to fossil sources.

-

Will shale gas come to Antwerp?

No. Ethane – one of the raw materials for Project ONE – is a by-product of natural gas, which we import to Antwerp by ship.

The United States extracts natural gas for local energy supply. The vast majority of this gas is methane, but it also contains smaller amounts of ethane, butane and propane. For the petrochemical industry, the ‘by-product’ ethane gas is very valuable as it is an important feedstock that can be converted into high-value chemicals. The ethane gas is thus put to good use and avoided being released directly into the atmosphere via flaring.

Shale gas suffers from a negative image. This goes back to the early years when there were teething problems. Meanwhile, the industry has professionalised over 20 years and there are strict rules for start-up and operation.

INEOS works with ethane suppliers committed to reducing greenhouse gas emissions and methane loss to an absolute minimum. Leading suppliers such as Range Resources (with 0.013% methane loss by 2022, a 69% reduction compared to 2019). Antero and SWN are also actively working to minimise their environmental impact and report their progress to government and sustainability bodies (see Range Resources and Antero sustainability reports).

Moreover, the ethane gas that INEOS imports into Antwerp is transported by ships powered by ethane gas instead of heavy fuel oil. This use of gas as fuel reduces sulphur and carbon dioxide emissions compared to conventional fuels, contributing to cleaner and more environmentally friendly logistics.

Does Project ONE promote shale gas extraction in the US?

The claim that Project ONE has a significant impact on shale gas volume is completely unfounded. In 2022, the United States produced 28.6 trillion cubic feet (Tcf) of shale gas, as reported by the US Environmental Protection Agency (EPA). Converted into tonnages, this amounts to 600 million tonnes per year. To put this into perspective: Project ONE uses just under 2 million tonnes of ethane, representing about 0.33% of the total amount of shale gas produced in the US. -

Should INEOS not produce more bio-based plastics?

The introduction of bio-based raw materials for the production of plastics is a very promising evolution. Although it is not yet possible to make all plastics from bio-based raw materials, we are fully committed to increasing the amount of bio-based raw materials we use, especially in Belgium:

- Biovyn, production of PVC from biomass: at our INOVYN site in Jemeppe, we have made it possible to produce PVC with ethylene produced from a biomass that does not compete with food production. In this way, there is a reduction of CO2 emissions of more than 90 percent compared to production from fossil raw materials. This supply chain has been fully certified by the Roundtable on Sustainable Biomaterials (RSB), an independent third party. Biovyn can be found, for example, in the upholstery of the Polestar 3 car, but also in prosthetics and window profiles.

- Bio-attribution of renewable raw materials: ‘bio-attribution’ expresses the extent to which fossil raw materials have been replaced by renewable or bio-based raw materials. Ineos O&P North Lillo offers a range of Bio-Attributed Olefins and Polyolefins, based on renewable bio-based raw materials that do not compete with food production. Their supply chain is fully certified by the Roundtable on Sustainable Biomaterials (RSB), an independent third party.

-

Should INEOS focus more on recycling instead of producing new plastics?

INEOS is strongly committed to reduce plastic waste. It is not the plastics themselves that are the problem, but the fact that they are thrown away in to the environment, sent to landfill, or incinerated. According to INEOS’ vision, we have to handle plastics with care, precisely because they are such valuable materials. That’s why INEOS invests heavily to support the recycling of plastics. In this way, all polymers produced by us (such as polyethylene and polypropylene produced on the basis of Project ONE-output) can be fully recycled.

INEOS is investing to support different forms of recycling. We develop products that lend themselves to mechanical recycling so that recycled material can also be used for high-quality applications, and we incorporate recycled plastics in to our products. We invest in the development of our processes to use bio-based raw materials or waste plastics as raw materials for new plastics. Advanced recycling (also called chemical recycling) is a developing technology. As we commercialize this technology, we will be able to produce more plastic from recycled products, creating a market for waste plastic.

All this is in line with our commitment of the INEOS Pledge, as plastics are a valuable material. We have committed to incorporate at least 850 000 tonnes of recycled and bio-attributed material in our polymer products by 2030. We previously committed to use an average of 30% recycled material in products for polystyrene packaging in Europe by 2025; to market a range of polyolefin products for packaging in Europe with at least 50% recycled material, to ensure that 100% of our polymers are recyclable.

Here are some concrete examples:

– When you see packaging, you don’t see that it consists of several layers. In fact, all those different layers have specific functions: rigidity, transparency, printability, sealability, barrier…. And to exploit each of these qualities, different materials are combined. Moreover, additional layers are needed to make all those layers compatible. However, these many layers also make packaging more difficult to recycle.

That is why the colleagues at our R&D centre in Neder-Over-Heembeek focused on “mono-materials“. Thus, they developed an upright bag packaging in mono-material that consists of more than 95% polyethylene and is fully recyclable. Indeed, polyethylene has emerged as one of the best monomaterials because of its intrinsic qualities and because the recycling chain was already in place.

It also produced a second rigid MDO monomaterial roll with more than 50% plastic waste – an absolute first in the market. This was helped by the investment in a high-tech, multi-layer MDO line to work with customers to develop solutions that they can apply directly to their own production lines.

Read more about it in this report on our R&D centre in Neder-Over-Heembeek– Upgrading plastics for successful combination with recycled material Each time a polymer (such as polyethylene and polypropylene) is mechanically recycled, the quality of the material decreases. This is why these recyclates are usually used in low performance and rather inexpensive end applications such as flower pots and garbage bags. The goal of INEOS is to increase the value of recycled polymers so that they are equivalent to ‘virgin’ plastics. In our research centre in Neder-Over-Heembeek we have succeeded in making products that meet the demanding performance characteristics required by our customers, whilst containing more than 50% of recycled plastic. These products are now fully commercialised under our Recyl-IN brand name.

– Advanced (chemical) recycling of polyethylene and polypropylene. Instead of making plastics based on naphtha (from crude oil), INEOS has started a partnership with the recycling company Plastic Energy to break down used polyethylene and polypropylene to their base molecules so that they can be reused as a new feedstock. After first successful tests in 2020, INEOS and Plastic Energy are now developing a project to build a new installation that can carry out this process on a large scale.

– Depolymerization of styrene. INEOS Styrolution has already made a breakthrough for chemical recycling by depolymerizing polystyrene waste: laboratory scale production of new polystyrene based on recycled styrene monomers. For example, old yoghurt jars can be reused half in new products. This happens at the site of Styrolution in Antwerp, the largest polystyrene installation in Europe. Soon a partnership will be entered into with waste processing company INDAVER whereby polystyrene waste will be recycled into pure styrene monomers. Already in 2022, a demo plant will be operational that will be able to recycle 15,000 tons. This project fits in Styrolution’s efforts to make plastic products based on waste or renewable raw materials.

-

Where will the ethane for Project ONE come from?

The ethane for Project ONE is a by-product of shale gas. In the United States, shale gas extraction has made the region self-sufficient for energy. The ethane is extracted from natural gas: its extraction is needed to make the gas suitable for heating, for example. Ethane used to be flared on site for this reason, until it was realised that it could be put to good use in the chemical sector.

INEOS also extracts ethane from the North Sea, but there is not enough supply to meet European demand. Therefore, we import ethane from the US for Project ONE, where it is abundant. In the current political context, the US is the best alternative to ethane from outside Europe.

-

How does an ethane cracker differ from a naphtha cracker?

Today, ethylene is produced in two ways: ethane-based and petroleum-based (naphtha). Today, naphtha is the most widely used raw material in Europe. Project ONE, however, will work on the basis of ethane, a by-product of natural gas.

Ethane is today the most efficient feedstock for ethylene production. This is because the molecular structure of ethane already closely approximates that of ethylene. Naphtha is less selective for ethane: its cracking releases many more by-products. To produce 1.45 million tonnes of ethylene, our cracker consumes 1.9 million tonnes of ethane, while a naphtha cracker needs 4.8 million tonnes of naphtha. That’s more than double.

Moreover, crude oil has to undergo a lot of refining steps before it can be used as naphtha. Ethane production, as in Project ONE, emits less than half the CO2 compared to the naphtha-based alternative for this reason, among others.

To trigger the chemical reaction of cracking, you need a lot of heat and thus energy. Project ONE will get this energy from the hydrogen automatically released during ethane cracking. With this, we can already fill 60% of the heat requirement. In petroleum, there are on average only 2 hydrogen atoms per carbon, in ethane there are 3. So in a naphtha cracker, you will always have to sacrifice part of the petroleum as fuel to make the cracking process possible. With ethane, you choose the most energy-efficient production process, which contributes to much lower CO2 emissions.

INEOS also has its own naphtha crackers, which play an important role for the circular economy with chemical recycling and bio-based feedstock. However, for the production of pure ethylene, naphtha crackers are not as efficient as the Project ONE ethane cracker, so this is the best and most environmentally friendly way to produce pure ethylene. Instead of talking about a “fossil lock-in”, let’s talk about a “naphtha lock-in”. Project ONE’s ethane cracker will reshuffle the market by making CO2 more expensive for the oldest and most polluting installations.

-

Is there a demand for ethylene?

A company does not invest 4 billion in a project without first doing its homework thoroughly. The same obviously applies to INEOS and its investment in Project ONE.

There will still be a need for new ethylene and, of course, this ethylene must be produced as efficiently and environmentally friendly as possible. The market demand for ethylene with a low carbon footprint is significant and cannot be supplied by older and less efficient plants. Project ONE is therefore part of the solution.

So what is new ethylene needed for?

- To compensate for the degradation of plastics during mechanical recycling, new material must also be added. So for that, you always need new ethylene.

- To ensure certain high-performance applications where there is no risk tolerance for lower performance. For example, for medical applications, water transport pipes that need to last 100 years underground, wind turbines,…

The market forecasts an average annual growth in demand for ethylene of 4% over the next five years. According to IHS Market forecasts, ethylene will be imported into Europe for the next 5 years.

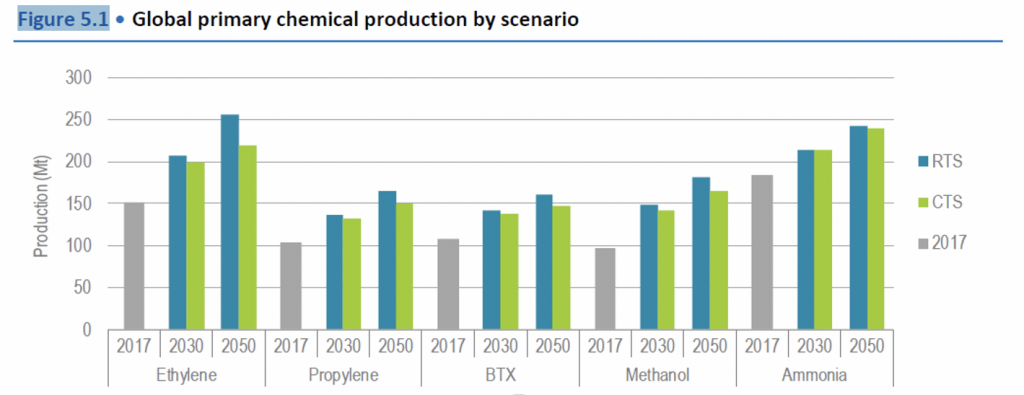

Even in the International Energy Agency (IEA) sustainable scenario[1], the demand for basic chemicals such as ethylene and propylene will increase by about 40 percent between 2017 and 2050. This is under the influence of a rising world population, rising prosperity and social evolutions (e.g. less demand for disposable plastics such as plastic bags, more demand for electric car components).

This sustainable scenario, with fewer emissions and more recycling, reduces the demand for new basic chemicals by 7 percent compared to the baseline scenario. Considerable efforts in recycling are therefore useful, but not sufficient to meet market demand. The production of new ethylene and propylene, as Project ONE will do, provides an answer to society’s need for these basic building blocks.

[1] The Clean Tech Scenario (CTS) by 2050 includes a 45% reduction in direct CO2 emissions from chemistry despite a 40% increase in demand for basic chemicals. It also includes a (nearly) tripling of the global average collection rate of plastic waste.

-

What is ethylene used for?

Project ONE will convert ethane to ethylene. Ethylene is one of chemistry’s main building blocks from which many products are constructed that are essential in everyday life: building materials, medical applications, clothing, windmill components, light packaging materials, lightweight parts for cars, and many more.

Want to know more? Watch the video on the production of drinking water pipes or read why ethylene is your sports shoe’s biggest supporter.

-

Are there no alternative raw materials for the shale gas from the United States?

Today, there is no fully-fledged organic alternative to ethane.

The bio-based alternative bioethanol is only viable and acceptable from a sustainability perspective in places where it does not compete with the food industry. Given the amount of space required to have sufficient volumes, bioethanol is only used in very specific areas (such as Brazil with its sugar beet plantations).

Sugar beet produces 5,000 litres of ethanol per hectare or 3.95 metric tonnes of ethanol/hectare. Applying this to Project ONE: 633,000 hectares of sugar beet are needed to feed an ethane cracker to produce one and a half million ethylene. By comparison, Flanders has 622,000 hectares of agricultural land. So this integral area would not suffice on its own and would mean that this land could not be used for food production.

Similar reasoning applies to the availability of recycled raw material. In 2021, 30 million tonnes of mixed plastic waste was available in Europe. For a cracker with the capacity of Project ONE, you already need a third of that, while you would need 150 million tonnes for Europe’s current ethylene capacity. That is not simply not available right now.

-

Will Project ONE create jobs?

Absolutely. In fact, with this investment, INEOS is creating 300 high-quality long-term jobs and 150 contractor jobs on the site and a multiple of them indirectly in the region. The arrival of Project ONE thus benefits employment in the port of Antwerp.

Interested in a job at INEOS? Check the vacancies at all our Belgian sites

During the construction phase, millions of man-hours will also be performed, with around 3,000 contractors working simultaneously on the Project ONE site during peak periods. For the construction, INEOS is calling on a lot of local construction companies. For example, Warsco is installing the mobile office units, Cordeel will erect the administrative campus, the civil works have been awarded to Denys-Aertssen and Mourik and Aertssen and Franki – De Waal has screwed 20 .000 pile foundations into the ground. Stadsbader Contractors and MBG are contributing to the realisation of the ethane tank. Crane work is provided by Sarens. And these are just a few examples of the many works that have been completed, are underway or still in the planning stage before Project ONE will be completed in 2026.

A lot of people elsewhere are also busy preparing for Project ONE. And once Project ONE is operational, jobs will be added. Project ONE thus creates 450 direct jobs: for 300 INEOS employees and 150 employees of contractors.

For every employee at its own site, Project ONE also creates five jobs at other companies.What kind of direct jobs does Project ONE create?

- Most jobs have a technical profile, both for the 300 INEOS employees and the 150 contractors who will work for Project ONE.

- The operation of the cracker involves 35 engineers and technically skilled workers, complemented by 110 operators who will work in shifts to man or mistress the cracker 24/7.

- In addition, there are 110 jobs in Project ONE’s technical department: engineers, bachelor of chemistry…

A lot of people have already been recruited. Would you also like to be part of our team? Then be sure to check out our job offer.

-

Is working in the chemistry industry safe?

The safety of our employees is our top priority. With our ‘Zero Accidents’ objective, we are doing our utmost to reduce the number of accidents to zero. We are well on our way to achieving this, having scored 0.17 on the OSHA scale (0.17 injuries per 200,000 hours worked) by 2022. For reference, if you calculate with 40 working hours per week, that’s about 2,000 per year (52 x 40 = 2,080).

-

Can I work for INEOS?

INEOS is always looking for talented and motivated colleagues. Keep a regular eye on our website for vacancies and other opportunities.

Do you want to be part of the Project ONE team? You can find those vacancies here.