When ethane is cracked, a mixture of different substances is produced, including the so-called C3 fraction. This contains a mix of propane and propylene, two very similar substances that each have their own applications.

The C3 splitter separates propane and propylene based on their difference in boiling point. Because the boiling points of propylene and propane are only about 5 degrees apart (-47.6°C vs -42°C), the separation is not easy. Therefore, sufficient height is required to perform the separation as effectively as possible. This makes the C3 splitter, at 100 metres, the highest column in the Project ONE installation because it requires 175 separation plates.

Did you know that the propane from the C3 splitter is send back to the furnaces? This is how we close the loop.

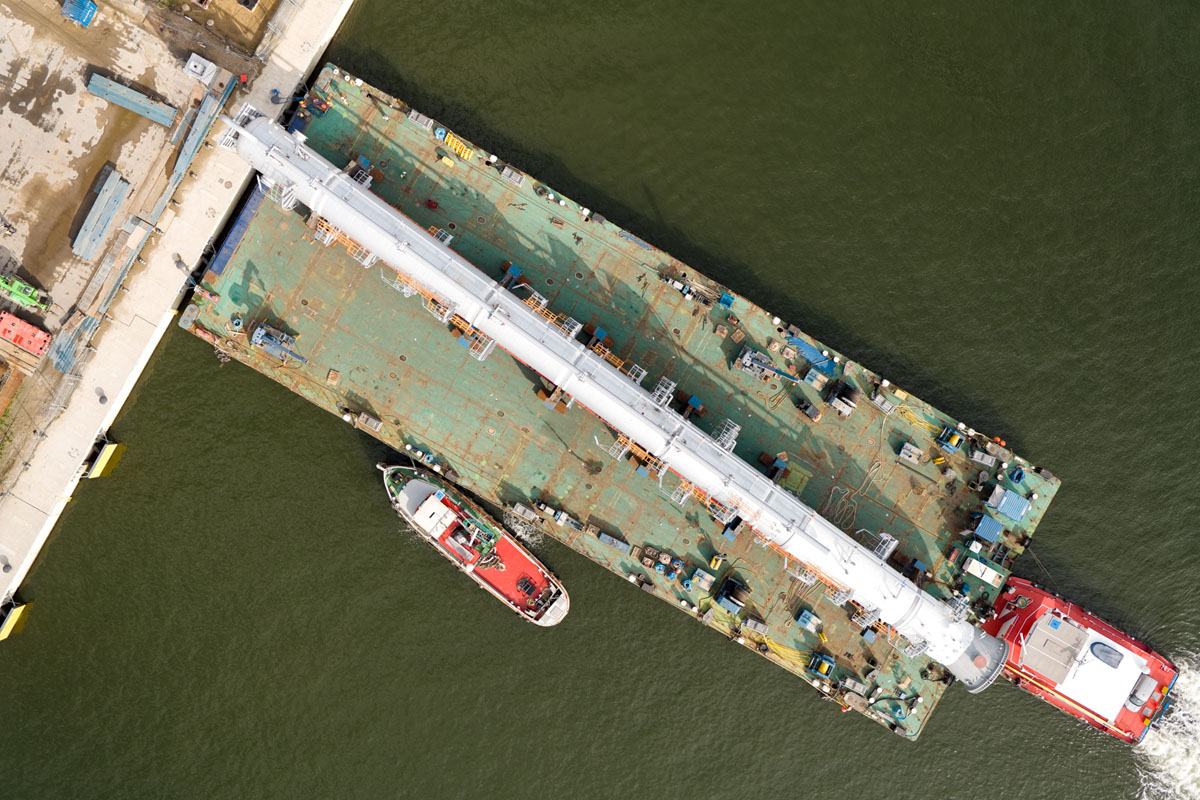

A pontoon transported the C3 splitter by water to the Project ONE quay. The pontoon departed from our marshalling yard, where parts are delivered and temporarily stored, and sailed through the Kanaaldok, passing the Noordlandbrug before finally mooring at Project ONE. In August, the “Strong Sofie” crane will hoist the splitter into place. At 100 metres high, it will become part of the skyline of Project ONE.