At INEOS’ site in Lillo, we’re producing 2 important plastics – polyethylene and polypropylene – in the form of small granules or ‘pellets’. These pellets are sometimes lost during shipment and transport. Are they harmful to the environment? And what measures are we taking to prevent them from being lost? Supply Chain Manager Philippe Neirynck is happy to tell you more about this.

Zero Pellet Loss, a concern for all of us

“The Zero Pellet Loss initiative was launched within the Ocean Clean Sweep programme – a pact to join forces and prevent plastic pellets from entering the environment. We signed this manifesto along with other companies from industry and the port of Antwerp. And that’s not all.”

We also oblige our partners, suppliers, and carriers to co-sign this pact. We can’t do it alone, we need each other.

“Our ambition is to remove all of the granules, including the very last ones.”

No longer through the mesh of the net

How can these pellets get into the environment? “The plastic granules are very resilient. When filling the trucks, they often jump up and remain on the vehicle. When we drive away from the site, the wind and speed blow them onto the public road: and from there into canals, sewers or rivers.”

To counteract this, we’ve created all kinds of measures in a variety of areas.

- Clean trucks. Among other things, pellet loss can occur during logistics operations. When filling the trucks, we now provide ‘caps’ over the silo conduits, which ensure that the pellets do not end up on the truck as quickly. When the trucks drive outside, they get a thorough check: we ask drivers to blow the very last pellets from their vehicle with an ‘air gun’. After that, an inspector comes to check this once more visually.

“In the beginning, drivers asked us if we were crazy. But we also want to get rid of those last 5 pellets before they drive out. That’s in accordance with our zero tolerance policy.” - Clean land. We make sure that the granules cannot leave the site. With filter basins and separation wells, for example, which are emptied regularly. With special enclosure walls too, we don’t give pellets a chance to blow outside.

- Clean roads. “We have the strip along the Scheldelaan swept once a week by a special broom wagon. They often ask us whether this is worthwhile, as hardly any pellets are swept up. That’s precisely the point. Should one of our preventive measures have failed, this is our extra buffer.”

- Awareness. “This is a collaborative project. All kinds of profiles are involved, from truck drivers to product designers. That’s why a general change in mentality was needed. With thorough sensitizing, often in the form of videos. It’s long-term work, but we’re already seeing a big difference. Everyone is working on it, everyone is convinced that it’s necessary. Each person in the chain is very attentive, and when they notice something that is not okay, they react immediately.”

A future without pellet loss

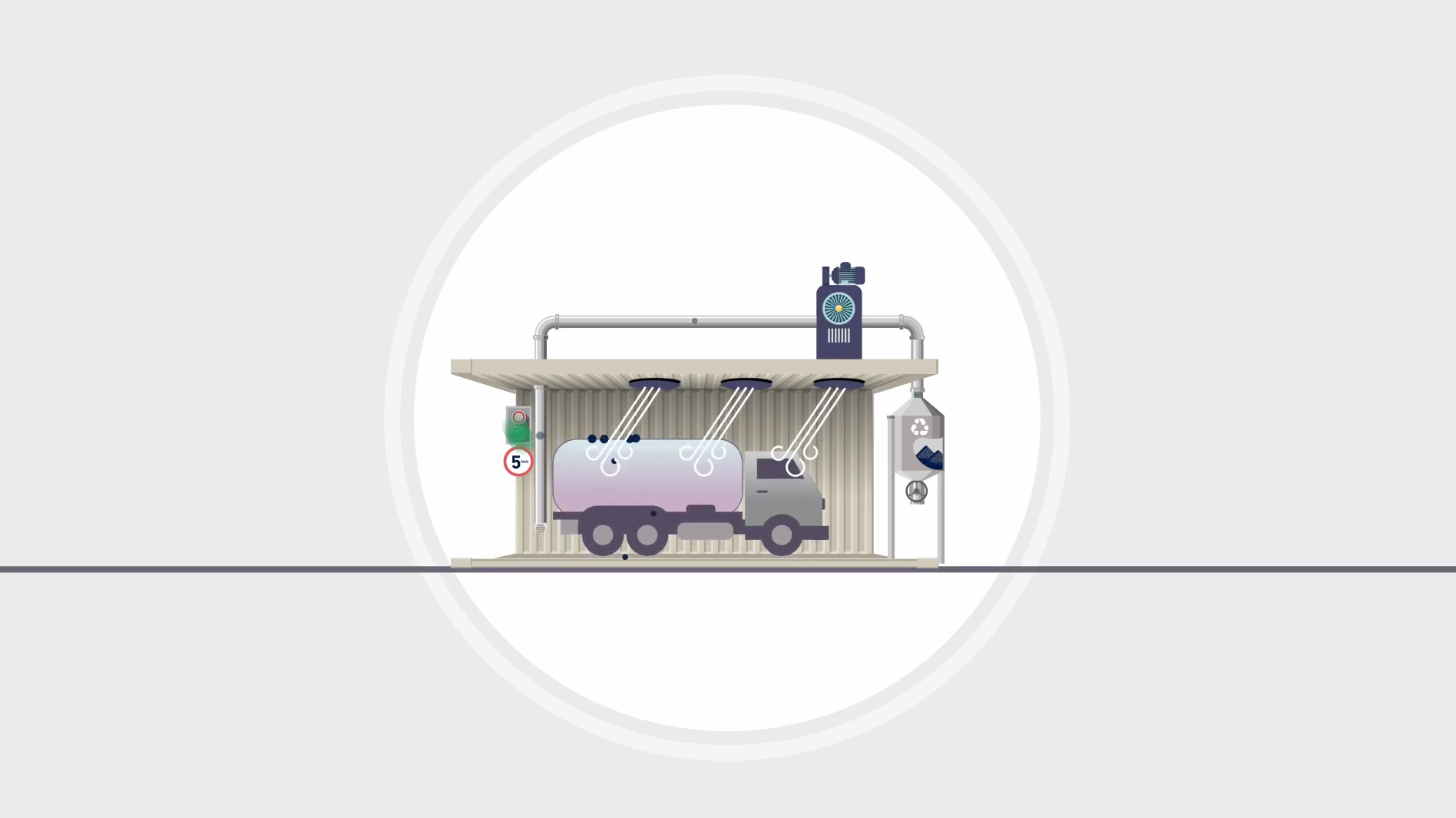

“The story of pellet loss is one of historic pollution. The granules are present on the banks of the Scheldt. That needs to be addressed – and we are really using all means possible to prevent this. For example, there now is a blow-off tunnel on the site that blows pellets off the trucks in one go.

The pellets themselves are not harmful to humans. But they’re still waste and they don’t go away by themselves.”

Every year, we collect about 3 tons of pellets in various places in our plant. And they get a second life. They are processed into lower-quality applications: sewers, garbage bags, pots for plants… Companies that are interested can purchase them at a lower price. The better the recycling, the easier to use in an application.

“Artificial granules do have a place in our society, but not as waste. We are against waste, because it’s of no use to anyone. That’s why we continue to invest in equipment, awareness and preventive measures.”